Chapter 1. How sensors work. Use of sensors in the server room

What are the sensors?

In general, sensors are measuring instruments used to capture signals of a specific type from the environment that can provide us with important information. Sensors are an integral part of larger measurement systems or control systems, which are now an indispensable element used not only in the world of technology, but also in business and everyday life.

The definition of sensor

The sensor is the first element of the measuring path that converts the measured quantity into a measuring signal (Czabanowski, 2010).

In other words, the sensor is the device that makes, what we want to investigate or measure, can be registered by the measuring device by converting it into a signal understandable by this device.

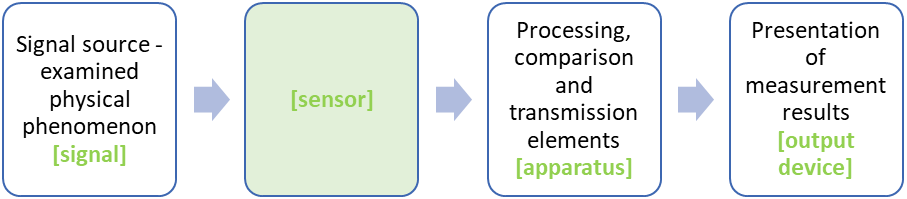

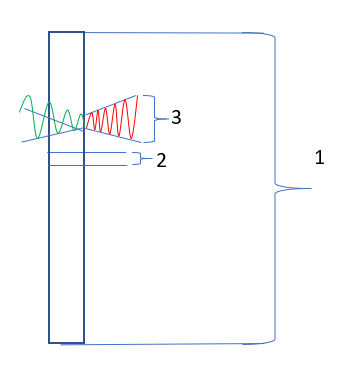

According to R. Czabanowski, a sensor can also be called a gauge or a measuring transducer of a physical quantity. The latter name indicates the sense of the sensor operation, i.e. the conversion of a physically observed quantity (e.g. heat) into a signal understandable to measuring devices expressed in a specific “language” of a given device (e.g. degrees Celsius) (Fig. 1).

Fig. 1. Measurement path – from signal to output device

Source: own elaboration based on (Czabanowski, 2010)

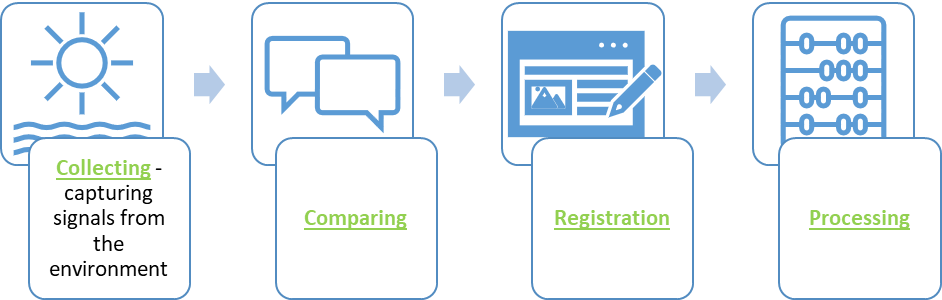

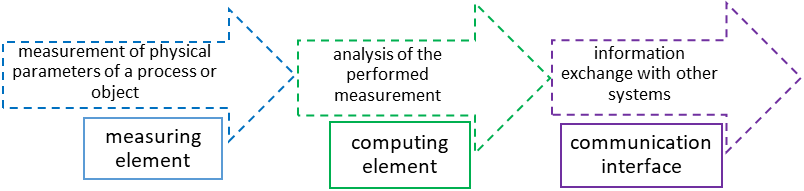

The above diagram deliberately delimits the place of the sensor in the entire measuring apparatus to indicate its important role in capturing the signal. In fact, sensors are an integral component of the entire measurement system, without which they will be of little use on their own. They are also the first element of the entire measurement path. Also, the entire measuring equipment and additional devices, without efficient sensors, will not perform their tasks. It is worth noting that the measuring system is the entire apparatus consisting of measuring devices and additional devices, which through the cooperation of all elements fulfilling specific functions enables the implementation of several important activities (Fig. 2).

Fig. 2. Activities taking place in devices of the measuring system

Source: own elaboration based on (Czabanowski, 2010)

The input signal, i.e. the signal from the environment, can be a mechanical, pneumatic, light or electrical signal. The processing of this signal consists in its mapping in the so-called an abstract image or on such processing of the information contained in the input signal, as a result of which a quantitative result is obtained. The result of the measurement and processing process will therefore be a certain quantity expressed in a specific unit of measurement.

Measurement process using sensors

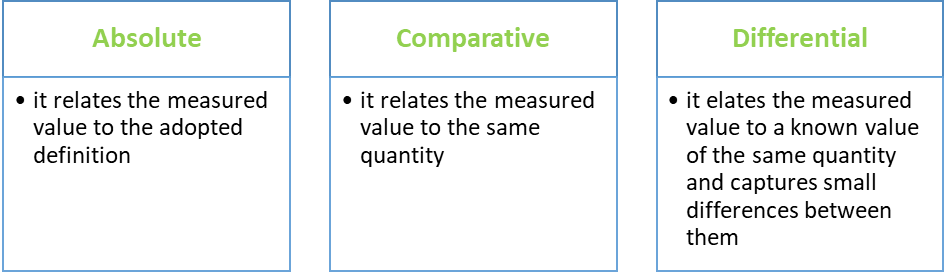

Measurement processes differ from each other, both depending on the method used during its implementation, and depending on the method of obtaining measurement results (Fig. 3).

Fig. 3. Basic classification of measurement methods

Source: own elaboration based on (Czabanowski, 2010)

A measurement method classification, named Core for the purposes of this course, refers to the comparison of a signal value with a specific baseline value indicated. When using a measurement, you should always remember what it is, so that you can correctly interpret the result obtained. The result itself can also be obtained and captured in various ways. In this case, we can talk about direct and indirect measurement (Fig. 4).

Fig. 4. Classification of measurement methods with regard to the method of obtaining measurement results

Source: own elaboration based on (Czabanowski, 2010)

It is worth noting that the direct method is simpler than the indirect method, allowing for quick reading and obtaining the result. In the case of the indirect method, it is necessary to convert certain values, which often requires the use of additional devices in the measurement process.

The course of the measurement process also depends on the type of signal, i.e. the form in which it occurs and the changes that occur in it. Most often, in the case of measurements, we deal with electrical signals, which can be in analogic or digital form. All this means that the measurement process will require processing of the input signal.

Properties of sensors

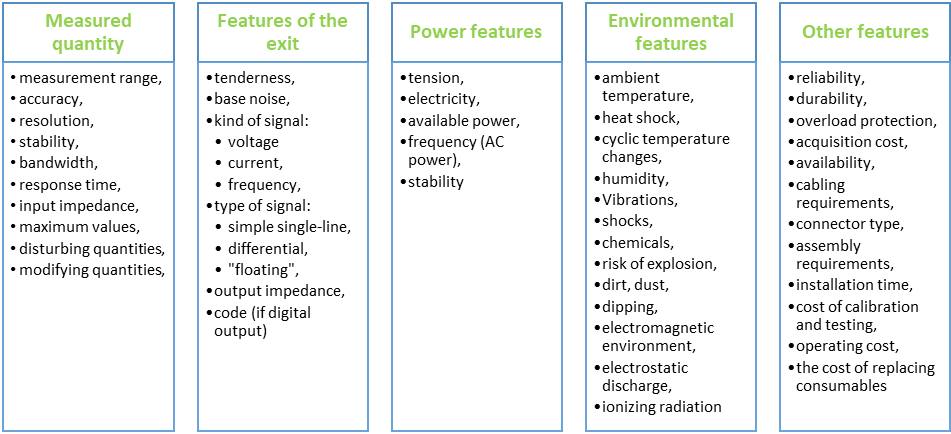

The measurement process and the degree of its complexity mean that the sensors should be adequately selected and have specific properties (Fig. 5).

Fig. 5. Properties of the sensor considered during its selection

Source: (Skoczyński, 2018)

Speaking of sensors, W. Skoczyński draws attention to several basic features of sensors that determine the quality of the measurement performed. These include: range (1), resolution (2) and sensitivity (3) (Fig. 6).

Fig. 6. Range, resolution and sensitivity of the sensors

Markings: (1) sensor range, (2) sensor resolution, (3) sensor sensitivity

Source: own elaboration based on (Skoczyński, 2018)

Sensor range (1) allows to define from which minimum values to which maximum values of the input signal it is possible to obtain the output signal. In other words, it is the measuring range that is possible with the device. What happens when the sensor range is exceeded? This situation may result in its damage or even destruction of the sensor.

Sensor resolution (2) is the smallest change in the measured quantity that can be reliably detected by this sensor (Skoczyński, 2018). In other words, it can be said that this is the value that the sensor can detect, and if it is smaller, the sensor will not record any change.

Sensor sensitivity (3) is expressed as the ratio of the change in the output (final) signal to the change in the input signal. In other words, it is an effect that takes the form of a change in the output signal as a result of a change in the input signal (e.g. a change in the physical magnitude of the phenomenon we measure).

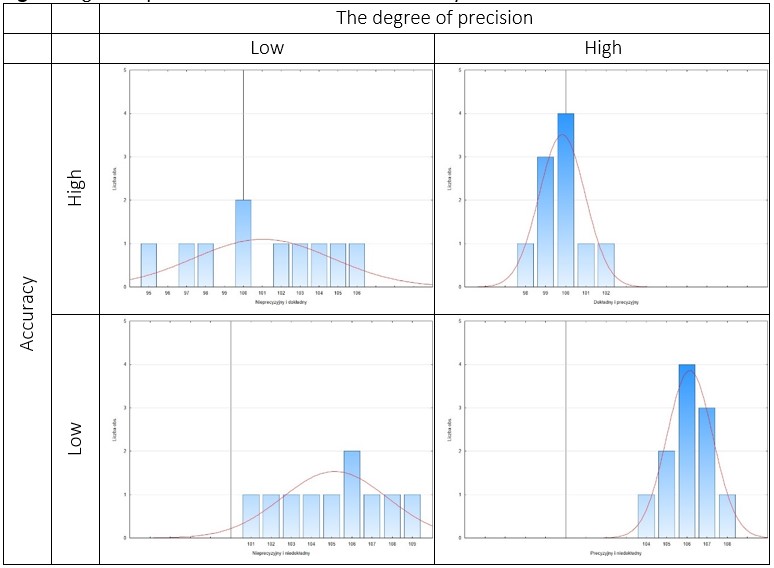

Fig. 7. Degree of precision and measurement accuracy

Source: own elaboration based on (Skoczyński, 2018)

The degree of precision of a measurement is expressed in terms of standard deviation values. If it is small, we can talk about a high degree of precision. The accuracy of the measurement will be expressed as the lowest possible value of the statistical error. Assuming that the correct value in Figure 7 is expressed as a straight line (black line for 100), you can easily see which measurement will have the lowest error value.

Selection of sensors

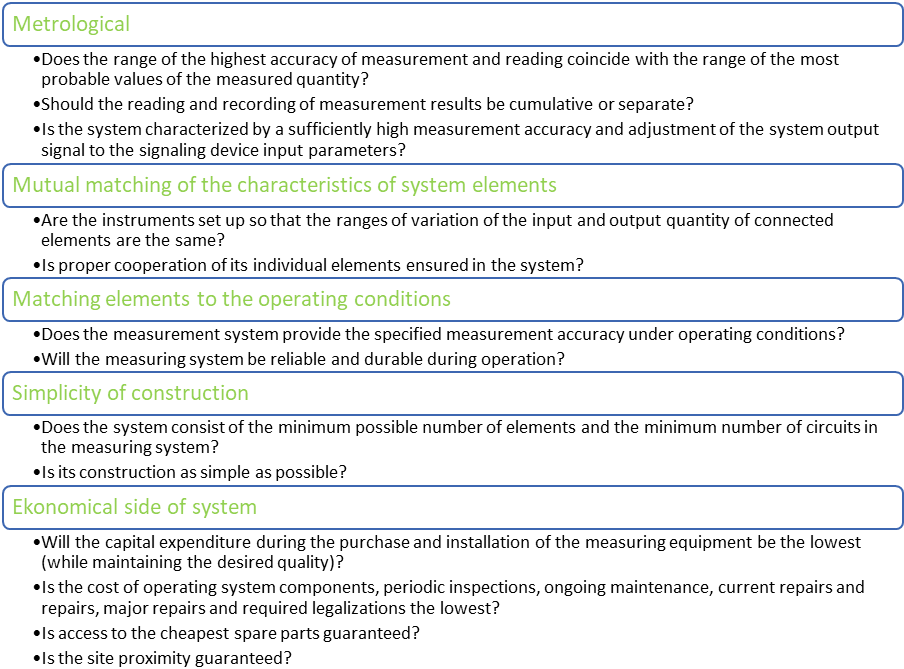

The answer to the question of how to select the appropriate measuring devices will depend on the purpose of the measurement. Generally, it can be said that the information indicated in the previous point relating to the precision and accuracy of sensors is the starting element in the process of selecting appropriate devices. In other words, they are essential, but they are not the only guidelines that should be followed. In this regard, it is worth asking yourself a few questions relating to certain characteristics of the measurement system (Fig. 8).

Fig. 8. Characteristics of the measurement system and auxiliary questions in the decision-making process about choosing the most optimal system

Source: own elaboration based on (Czabanowski, 2010)

Answers to these questions will allow us to assess whether a given measurement system will be the most optimal for the application we envisage for it. It is the indication of the main purpose of the measurement system application that will favour the indication of those elements that will be key.

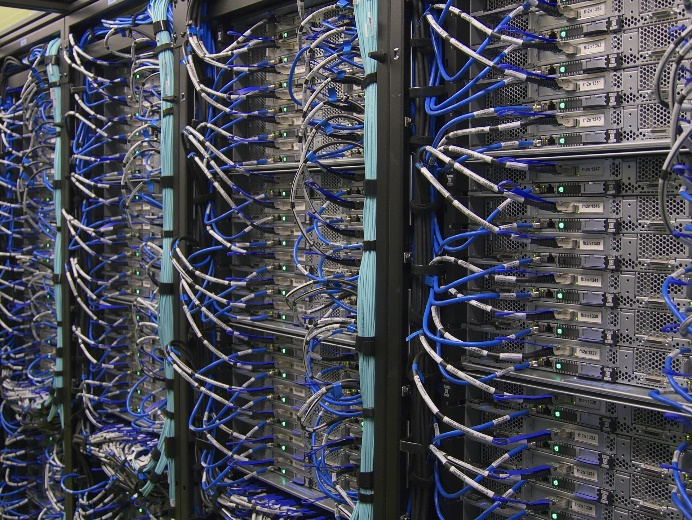

Source: Pixabay

The use of sensors in the Electronic Data Processing Center – in server rooms

Sensors play a significant role in servicing server rooms. Until recently, many of the protective activities were carried out based on specific human decisions, now all such processes can be automated. In this way, with the use of sensors and measuring equipment it is possible, inter alia:

- adequate protection of the room against unauthorized access (motion sensors, video surveillance, use of electronic access cards, etc.),

- control of temperature and humidity in rooms (use of sensors and air conditioners coupled with them),

- use of fire extinguishing systems (operating automatically on the basis of information received from the measurement system and equipped with an inert gas),

- use of a separate power supply network (switching on automatically based on the obtained data from sensors),

- overvoltage and residual current protection (sensors monitoring the status of specific parameters).

Sensors are those elements of the entire measurement system that are responsible for creating a signal carrying information about the state of the monitored process or device (Szulewski, Śniegulska-Grądzka, Nejman, 2019). Originally, they were designed to actively convert a selected physical quantity (e.g. its change), most often into an electrical quantity, easy to measure and further process (transfer) (Szulewski, 2018). Currently, it is desirable that the sensors can not only capture the changes taking place, but also generate feedback on their basis, which the measurement system can use in the future. It is related to the concept of machine learning (Szulewski, 2018). This concept fits in with the construction of artificial intelligence systems, which, based on previously indicated rules and algorithms, allow to detect the so-called outliers (e.g. events that may, in consequence, threaten the functioning of the tested system) (Christodoulou, Szczygieł, Kłapa, Kolarz, 2018). If the system was able to learn this type of situation, in the future it could itself identify potential places where undesirable phenomena occur, and diagnose their causes, and even prevent them.

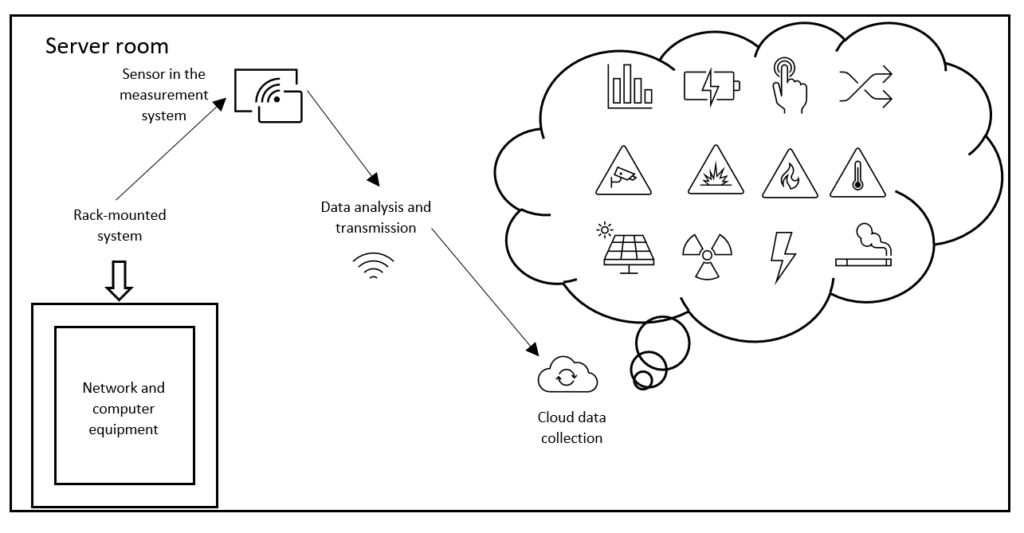

Currently, this is the direction of their development in sensor technology. This is due in part to both the need for detailed data and, on the other hand, a very large amount of data, which prevents quick and simple analysis. Thus, some of the monitoring processes need to be taken over by machines. In this way, cognitive sensor technology are created. Fig. 9 presents a diagram of the functioning of an intelligent analysing system with the use of sensors.

Fig. 9. Diagram of the functioning of an intelligent analysing system with the use of sensors

Source: own elaboration based on (Szulewski, 2018)

Each of the elements indicated in Fig. 9 (i.e. measuring element, computing element and communication interface) performs specific functions in the system. The measuring element measures one or more physical parameters of the tested process or object. This can be, for example, testing the temperature or air humidity in a server room, or testing the power level. The computational element analyses the obtained values basing on the previously set parameters (limit values). In the case of server rooms, these may be e.g. the temperature values that should be maintained in the room. The communication interface element in a smart metering system is responsible for providing feedback based on the results obtained. For example, when the temperature in the server room is exceeded, information is sent to the air conditioner control system, which turns on this basis. Learning of this type of systems in the server room may be based on many parameters, the mutual arrangement of which may mean different situations. For example, if the air temperature outside the building is very high and remains for a long time, and there have been previously reported power cuts, in certain situations, in the server room there may be a power outage, which will result in both an increase in the temperature in the server room and the cessation of servers’ functioning. It will therefore be necessary to prepare an emergency power supply.

In machine learning, it is important to be able to predict the effects of certain events and on this basis indicate which parameters may be useful for the system to react early. Hence, when building a measuring system in the server room, it is necessary to indicate what events we would like to avoid, and what should be the optimal parameters for the functioning of all server room elements. On this basis, it will be possible to develop a set of indicators relating to the proper operation of devices in the server room.

Source: Pixabay

Characteristics of an intelligent measurement system in a server room

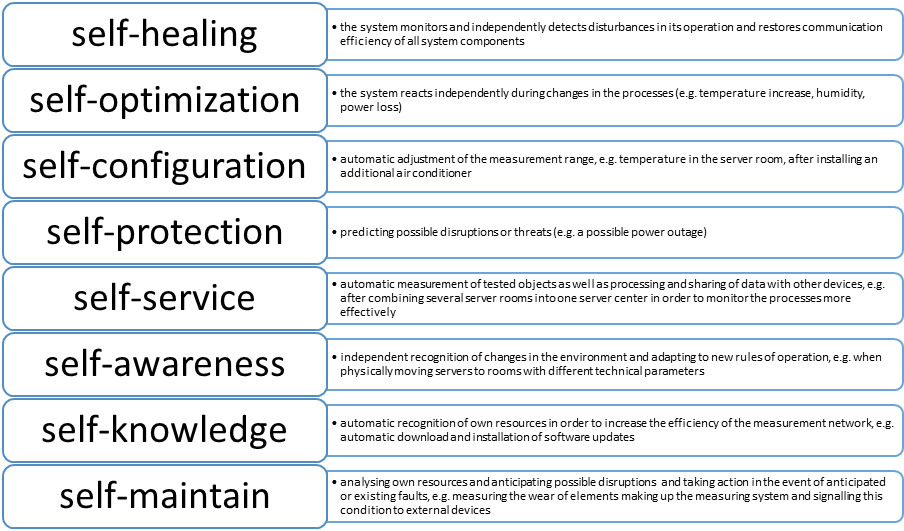

As previously mentioned, intelligent sensors are part of the entire intelligent measurement system. The use of such a system in a server room can be very helpful in its operation. Fig. 10 shows the features of an intelligent measurement system that can be used in a server room.

Fig. 10. Examples of features of an intelligent measuring system in a server room

Source: own elaboration based on (Szulewski, 2018)

Source: Pixabay

What can sensors in a server room be used for?

The most important requirements for server rooms are reliability and transmission capabilities (Bartkowiak, 2011). For this reason, it is necessary to monitor a number of different parameters of the functioning of both the server room and the processes taking place in the server room (Fig. 11).

Fig. 11. Functioning of measuring systems in the server room

Source: own elaboration

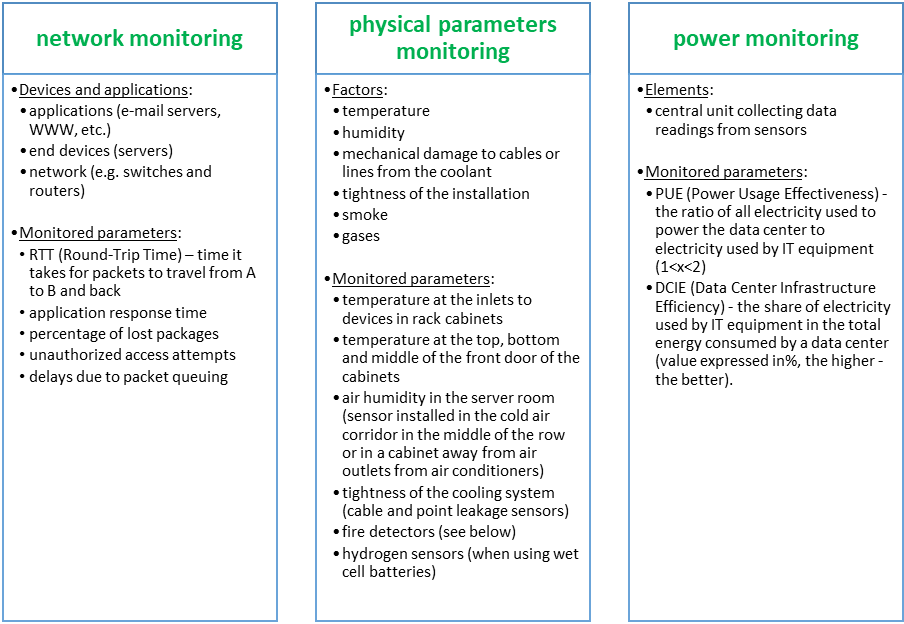

Monitoring of server rooms includes, among others (Kowalczyk, 2015):

- Network monitoring, incl.:

- network performance,

- the status of individual devices,

- server and application performance,

- network communication,

- Monitoring of physical parameters, incl.:

- temperature,

- humidity,

- mechanical damage to cables or pipes from the coolant,

- tightness of the installation,

- smoke,

- gas emissions,

- Power monitoring, incl.:

- the share of electricity consumed by individual IT equipment,

- total electricity consumption in the server room.

Ad. 1) In the case of network monitoring, the sensors will serve primarily the need to detect device failures or problems in network communication, e.g. a drop in data transfer speed. The reasons for this type of failure include: overload or failure of servers, disruptions in network communication due to hardware failure or human error (Kowalczyk, 2015).

Ad. 2) In the case of physical parameters monitoring, in addition to the obvious temperature control, it is also recommended to control the state of air humidity. Deviations from the optimal state in this regard may result in either overvoltages (when the air is too dry, which causes the accumulation of electric charges) or short circuits (when the air is too humid and water vapor begins to form on the devices) (Chipelectronics, 2019).

Ad. 3) In the case of power monitoring, you can compare the amount of electricity that is consumed by various devices in the server room, e.g. how much electricity the central unit collecting data from sensors consumes for cooling with the amount of electricity consumed by IT devices. Typically, the amount of energy each device consumes is measured either on uninterruptible power supplies or on power distribution units (PDUs).

Fig. 12. Devices and applications monitored in the server room and their operating status parameters

Source: own elaboration based on (Kowalczyk, 2015)

One of the more serious threats that can occur in a server room, and which can be easily detected using sensors, is fire. When there is a fire hazard, an important element is to equip the server room with an early warning system, because even a small amount of smoke and vapours from overheated components and cables can damage sensitive electronic devices (Bartkowiak, 2011). During the operation of servers, power of several hundred watts is released on the surface of one processor (Bartkowiak, 2011). This means that one of the most sensitive parameters in the server room will be to ensure and maintain the appropriate temperature, so that all elements of the server system can work optimally and not be exposed to overheating or melting, or as a result – ignition or dust. Through the use of DC-FMS systems (Data Centre-Facilities Management Systems), that, by connecting to sensors that enable measurement and reading of temperature information sent by devices, it is possible to react early to a potentially impending threat. In this way, they support the supervision of the server room operation. In this case, the sensitivity of a sensor that measures, for example, smoke measurements is quite important (Fig. 13).

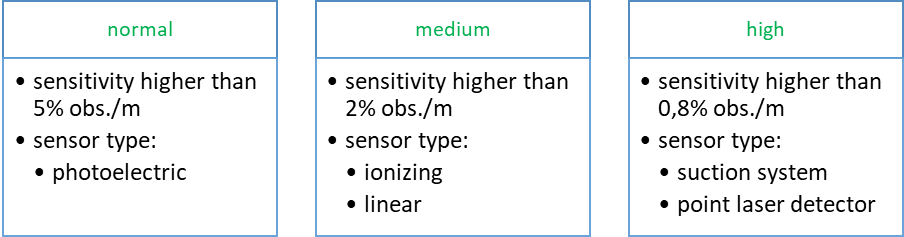

Fig. 13. Sensitivity categories in smoke detection systems according to the British Fire Protection Systems Association

Source: own elaboration based on (Bartkowiak, 2011)

The smoke measurement is carried out using a smoke sensor, which is based on the obscuration category, which is the amount of smoke that will block the light as a percentage over a distance of one meter. This value is expressed as a percentage per meter (% obs./m.) (Bartkowiak, 2011).

Ελληνικά

Ελληνικά Polski

Polski Slovak

Slovak Español

Español Lietuvių

Lietuvių Português

Português